Although any load is dependent upon material, geometry, and quench-ability, our capabilities are versatile enough to accommodate most tool steel, stainless steel, and other unusual processes associated with heat treating.

Services

Our Services & Capabilities

- Neutral hardening: Up to 60 inches long.

- Carburizing: Up to 60 inches long.

- Carbo-nitriding: Two continuous furnaces.

- Vacuum Hardening: Stainless and tool steel.

- Nitriding: Up to 115 inches long.

- Straightening and Aging

- Flame Hardening

- Precipitation Hardening

- Stress Relieving, Brazing

- Carbon Restoration

- Cleaning: Sand blasting, Aluminum oxiding, Glass beading

Bottom Load Vacuum

Service Overview

Aluminum Treating

County Heat Treat’s aluminum treating department consists of four furnaces. Three are capable of solution treating and aging and one is solely for aging. Dimensions and heating capabilities for the solution and aging furnaces are as follows:

60″ x 60″ x 60″ 1100 degrees F maximum

64″ x 120″ x 62″ 1050 degrees F maximum

72″ x 102″ x 80″ 1450 degrees F maximum

64″ x 120″ x 62″ 1050 degrees F maximum

72″ x 102″ x 80″ 1450 degrees F maximum

Aging Furnace

52″ X 72″ X 80″ 550 degrees F maximum

We offer the choice of air blasting or water quenching and have full straightening capabilities.

We offer the choice of air blasting or water quenching and have full straightening capabilities.

Shrink Fitting

The process of fitting a piece into a hole that is smaller than the piece itself. This is done by cooling the insert in liquid Nitrogen, causing it to shrink slightly, and heating the other piece, causing it to expand. The parts are then assembled. When the assembled parts reach room temperature, they will be fit together.

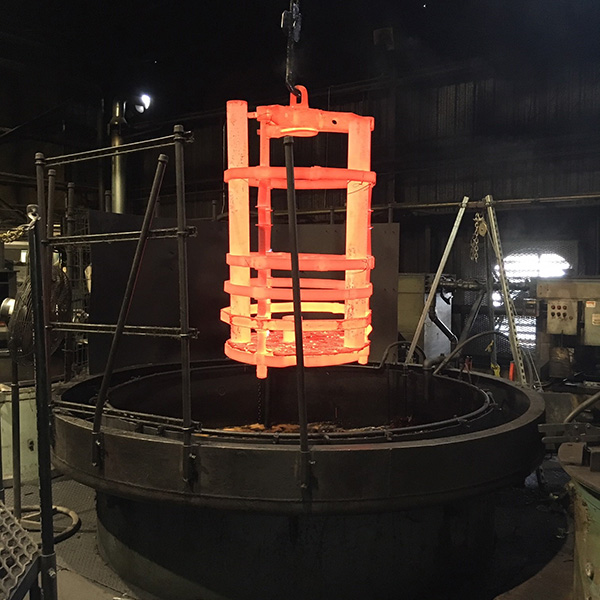

Vacuum Hardening

County has four vacuum furnaces used for hardening tool steels, stainless steels, brazing and solution annealing. Our vacuum furnace capacity is able to meet the most demanding needs.

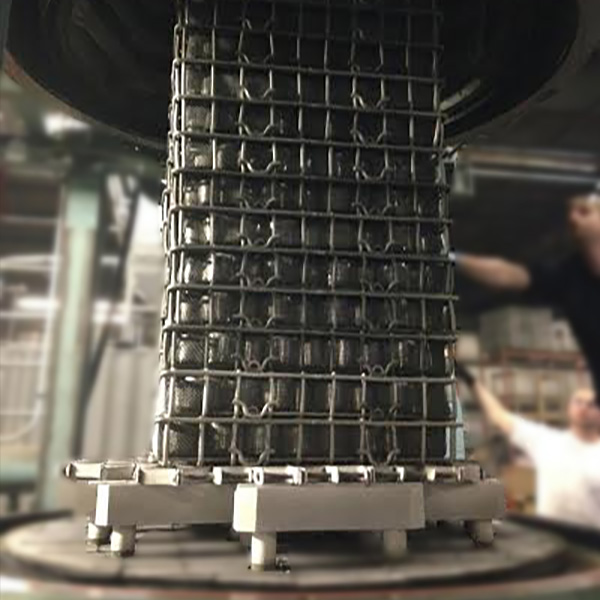

410 Material loaded on conveyor belt for hardening.

This is a load of stainless steel shafts racked in a vertical position and ready for heat treatment.

This is our bottom load vacuum furnace being loaded with 304 stainless parts for solution annealing.

Straightening

Unfortunately, distortion is an unavoidable product of heat treating. This may be caused by any number of factors:

- Choice of steel relevant to the heat treatment required

- Severity of machining

- Defects in steel

Depending on each individual’s job requirements, our Straightening Department uses hot and cold straightening, peen hammering or spot straightening to bring the product within finishing tolerances.

416 stainless steel

Nitriding

CHT’s nitriding furnaces are able to process parts up to 115 inches long and 38 inches in diameter, including stainless steel.

Unloading Nitride job

Neutral Hardening

Neutral hardening and gas carburizing of large pieces up to 60 inches long and 40 inches in diameter. Material being treated is transferred from our atmosphere pit furnace to an oil quench bath.

Flame Hardening

Flame hardening is a long-used effective form of localized hardening. Fast and efficient, this method requires an experienced eye to run the job. County has over 100 years of combined experience to ensure maximum quality and customer satisfaction.

A gear being torch-heated.

A gear being torch-heated.

A gear being oil-quenched.

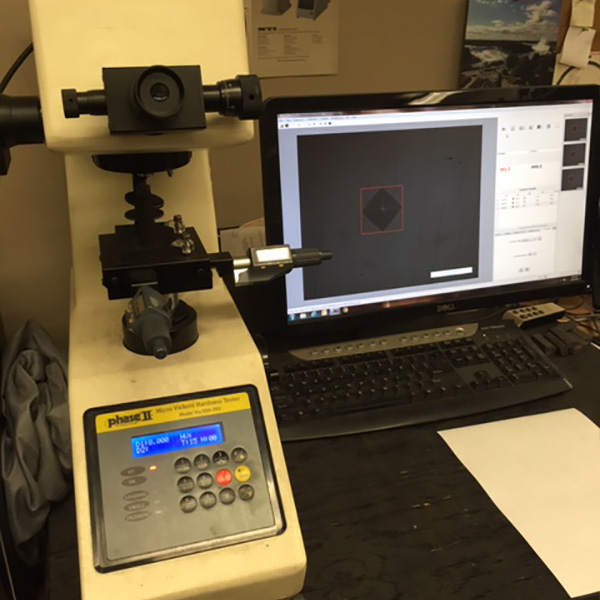

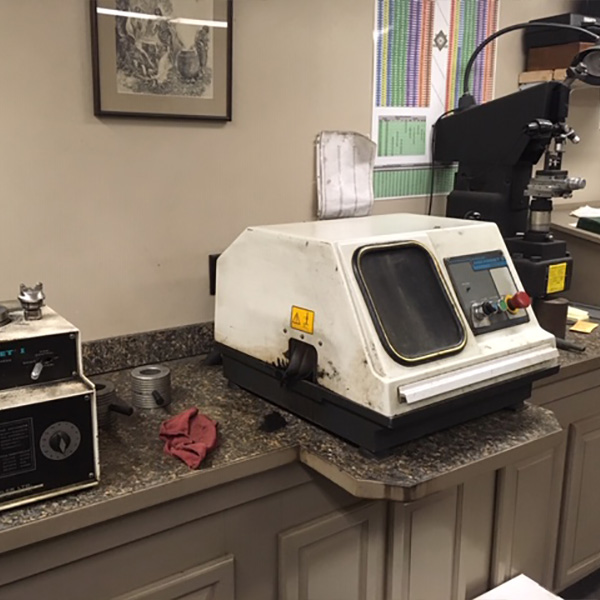

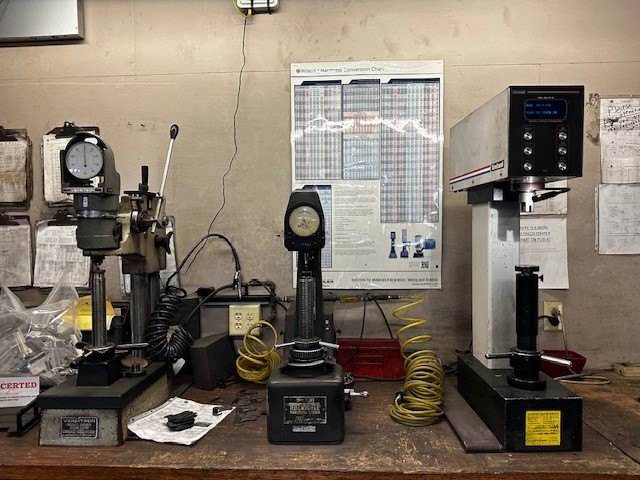

Inspection Department

Here at County Heat Treat, we are able to perform Rockwell and Brinell hardness testing as well as micro hardness testing.

Rockwell Hardness Testers

Brazing

In our four vacuum furnaces we vacuum braze using copper or nickel compounds. These are pictures of parts that were copper-brazed in a vacuum furnace.

Cleaning: The Finishing Touch

When desired, abrasive cleaning is performed in a variety of ways. Heavy-duty scale and discoloration are removed through sandblasting on a 72″ table blaster. Large volumes of small parts are tumble sandblasted. Other methods of cleaning include glass beading and aluminum oxide in sandblast cabinets.

A heat-treated component before and after glass bead treatment.

Before

After